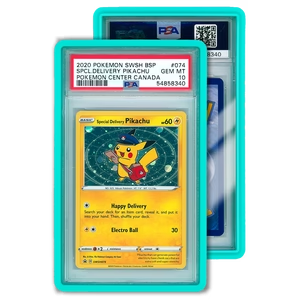

Graded Guard cases for CGC graded collectibles are essential tools for collectors who wish to preserve and protect their prized possessions. These cases serve as an additional layer of security for items that have already been professionally graded and encapsulated, ensuring that their value and condition are maintained over time. Collectibles such as comic books, trading cards, and other memorabilia are often subjected to various environmental factors that can compromise their quality, making proper protection a priority for serious collectors.

A graded guard case is specifically designed to accommodate the unique dimensions and structure of CGC encapsulations. These cases are crafted from durable materials that provide excellent resistance to external pressures, scratches, and potential impacts. The purpose of such cases is to safeguard the collectible against accidental damage, whether it be from handling, storage, or transportation. For collectors who invest significant time and resources into acquiring valuable items, graded guard cases offer peace of mind and long-term security.

One of the primary benefits of using graded guard cases is their ability to shield collectibles from environmental hazards. Exposure to sunlight, moisture, and temperature fluctuations can have detrimental effects on the condition of collectibles. Ultraviolet light, for example, can cause fading or discoloration of printed materials, diminishing their visual appeal and market value. Moisture can lead to warping, mold growth, or other forms of degradation that compromise the structural integrity of the item. Graded guard cases are often equipped with UV-resistant properties and airtight seals to mitigate these risks, ensuring that the collectible remains in pristine condition.

In addition to protecting against environmental factors, graded guard cases also provide a safeguard against physical damage. The rigid construction of these cases helps to prevent bending, cracking, or other forms of physical stress that could compromise the encapsulation or the collectible itself. This is particularly important for collectors who frequently transport their items to conventions, trade shows, or private exhibitions. The protective nature of the cases ensures that the collectible remains intact and visually appealing, even after extensive handling.

Graded guard cases also contribute to the aesthetic presentation of collectibles. Many cases are designed with a sleek and polished appearance that enhances the overall display value of the item. Clear and transparent materials allow collectors to showcase their graded collectibles without compromising visibility. This makes the cases ideal for display purposes, whether in a personal collection or a professional setting. The combination of protection and presentation ensures that the collectible retains both its functional and aesthetic value over time.

Another advantage of graded guard cases is their role in maintaining the authenticity and credibility of graded collectibles. CGC encapsulations are a testament to the authenticity and quality of an item, and protecting them with a graded guard case reinforces their legitimacy. Collectors often view well-protected items as more trustworthy and desirable, which can enhance their market value and appeal to potential buyers. For those looking to sell or trade their collectibles in the future, investing in high-quality protection is a strategic decision that can yield significant returns.

The durability and longevity of graded guard cases make them a cost-effective solution for collectors. While the initial investment in these cases may seem substantial, the long-term benefits far outweigh the cost. By preventing damage and preserving the condition of collectibles, graded guard cases help collectors avoid costly repairs or replacements. The value of well-maintained items often appreciates over time, making the protection provided by these cases a worthwhile investment.

Collectors have a variety of options when it comes to selecting graded guard cases, allowing them to choose a product that meets their specific needs and preferences. Factors such as size, material, and design play a significant role in determining the suitability of a case for a particular collectible. For example, some cases are designed with reinforced corners and edges to provide additional impact resistance, while others focus on lightweight construction for ease of transport. The availability of customizable options ensures that collectors can find a case that aligns with their priorities and enhances their overall collecting experience.

Proper storage and organization are also essential aspects of maintaining a collectible collection, and graded guard cases play a key role in this process. These cases are often stackable, allowing collectors to efficiently organize their items without sacrificing space. Stackable designs help maximize storage capacity while maintaining accessibility, making it easier for collectors to locate and retrieve specific items. By facilitating organized storage, graded guard cases contribute to a more streamlined and enjoyable collecting experience.

The use of graded guard cases also reflects a collector’s commitment to preserving the cultural and historical significance of their items. Many collectibles hold sentimental or historical value, representing a particular era, artist, or event. Protecting these items ensures that they remain a source of inspiration and enjoyment for future generations. Graded guard cases provide collectors with the tools they need to act as stewards of their collectibles, safeguarding them for years to come.

Innovation and technology continue to shape the development of graded guard cases, offering collectors new and improved solutions for protection and preservation. Advances in materials science have led to the creation of cases that are lighter, stronger, and more resistant to environmental factors. Features such as tamper-evident seals and integrated tracking systems provide additional security and peace of mind for collectors. These innovations reflect the evolving needs of the collecting community and underscore the importance of continued investment in high-quality protective solutions.

Education and awareness are also critical components of effective collectible preservation. Collectors who understand the risks and challenges associated with maintaining their items are better equipped to make informed decisions about protective measures. Graded guard cases serve as a tangible reminder of the importance of proactive care and responsibility in the collecting process. By prioritizing protection, collectors demonstrate their dedication to preserving the integrity and value of their items.

In conclusion, graded guard cases for CGC graded collectibles are indispensable tools for collectors seeking to protect and preserve their valuable items. These cases offer comprehensive protection against environmental hazards, physical damage, and other risks that could compromise the condition and value of collectibles. By enhancing both the functionality and aesthetic appeal of graded items, graded guard cases contribute to a more rewarding and fulfilling collecting experience. As the collecting community continues to grow and evolve, the importance of high-quality protective solutions remains paramount, ensuring that treasured collectibles can be enjoyed and appreciated for generations to come.